d2w™ grade 93389/C is an oxo-biodegradable additive based on a polyethylene carrier resin formulated for demanding processing application requiring a high degree of thermal stability, D2W appears as light brown particles.The product should be stored in cool dry conditions away from strong sources of light and heat. Storage temperatures should not exceed 30°C.

Under normal storage conditions the product has a shelf life of 18 months from the date of manufacture which is printed on the sack.Part used bags should be discarded.

D2W is an additive formulation that renders conventional polyolefins oxo-biodegradable.“Oxo-biodegradation” is “degradation identified as resulting from oxidative and cell-mediated phenomena, either simultaneously or successively” ("Terminology in the field of degradable and biodegradable Polymers and Plastics" CEN/TR 15351).

Polyolefin products made with d 2 w additive will abiotically degrade in the presence of oxygen. Degradation has been proved in accordance with the requirements of ASTM 6954-04 by passing ASTM 5510(RAPRA Report 46095). The ability of d 2 w products to comply with the biotic (biodegradation) tests of ASTM 6954-04 has been demonstrated by the loss of molecular mass achieved after abiotic thermal degradation, resulting in ultimate biodegradation of the material into CO2, water, mineral salts and biomass (RAPRA Report 46303, Pyxis report 30.7.05, and DPPA Chapt. 3, Eco-sigma Report Sept. 2008). The eco-toxicity sections of EN 13432 and ASTM 6954-04 require that no harmful residues are left - this has been verified for d2w additive. (OWS Report MST-4/1-d2wb&d2wc, Eco-Sigma Report Sept.2008).D2W additive does not contain heavy metals (defined by 94/62/EC Art 11 as lead, mercury, cadmium, or hexavalent chromium). d 2 w additive is safe for direct food-contact according to the European Union requirements for Direct Food Contact 1935/2004/EC and the US FFDC Act and regulations (RAPRA report 46137, and Keller &Heckman certificate 18.2.2009). It is the responsibility of the manufacturers of products intended for food-contact to ensure that all other materials incorporated by them comply with those requirements. If polymer products are correctly made with d 2 w, the additive will have no effect upon the strength and other performance characteristics of the product during its programmed service-life.Polymer products correctly made with d 2 w comply with the Essential Requirements of the EU Packaging Waste Directive 94/62/EC Annex II paras. 1, 2 and 3(a) (b) and (d).In addition to the above, d 2 w Additives and finished products have been extensively tested, according to the test methods prescribed in the UAE Standard 5009/2009 and BS8472.d 2 w products can met AFNOR TC51-808 Accord.

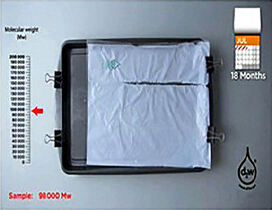

D2W packaging film degradation stage diagram

1 Month

The packaging film in this picture has been added with D2W oxidized biodegradable plastic additives and is set to decompose after 18 months

18 Months The packaging film after the 18th month had cracked. Because D2W oxidative biodegradable plastic additives contain natural mineral salts and degrading substances, they can promote the weakening and decomposition of polymer plastic chains

19 Months

The packaging film in the 19th month has been completely broken

20 Months The packaging film of the 20th month, small fragments whose molecular weight has dropped below 40,000. At this time, microbial biomass in the normal natural environment can erode these biological medium fragments. In the end, all that's left is carbon dioxide, water, cellular biomass, and nothing harmful remains.

D2W oxo-biodegradable plastics are not currently intended for composting.If sent to landfill d 2 w oxo-biodegradable plastics will degrade in aerobic conditions. In anaerobic conditions they become inert and will not emit methane.d 2 w oxo-biodegradable plastics can be recycled together with ordinary oil-based plastics. For long-life products, stabilisers should be added if necessary. Symphony’s d2w® technology is the only oxo-biodegradable plastic additive certified by ABNT under the Environmental Quality–Eco-Label program Internationally accredited by INMETRO – Certificate no 365.001/14